Determined to engage at the earliest stage of a project, we act as a central hub for clients completing a mix of both unitised and traditional stick-built facades.

Offering a complete end-to-end service from pre-construction to project handover, we guarantee innovation, safety and take sole responsibility in delivering remarkable buildings.

Urban Art

Pre-Contract Service Agreements

Assisting the architect and wider design team to fully develop the design allows us to ensure projects are delivered in line with cost plans, programme and built to deliver the client’s vision.

Pre-Contract Service Agreements or PCSAs are becoming common place within the fenestration industry, by appointing Clarke as your trusted façade contractor we get to know the project extremely well, build our relationship with the client, allocate a dedicated design and fabrication resource whilst giving technical advice and offering façade solutions to ensure the project is smooth sailing from day one. Our in-house team have vast experience with PCSA’s from highrise unitised schemes to traditional stick-built facades.

Engaging Clarke under a PCSA has many value added benefits

- Providing technical advice and design proposals

- Resolving any scope gaps between trades

- Provides client with better cost certainty

- Allows time to realise true value engineering

- Shortens design & procurement programmes once appointed.

- Speeds up sampling & Mock-up process

- Sole responsibility from concept to completion

Pre-Construction

We offer a fully collaborative pre-construction service benefitting clients when they chose to engage early with Clarkes. Engaging expert capability de-risks any scheme providing cost assurance, design buildability and a compliant procurement process. Our single point of service includes;

- Concept design

- System design and material selection

- Cost consultancy

- Prototyping and visual mock-ups

- 3D printing

- Programme, logistics and methodology advice

Our dedicated resource work closely with clients through early engagement workshops exploring solutions with a hands-on personal approach and with our vast knowledge of façade systems and products we consider all interfaces providing robust weather resistant, thermal, acoustic and fire-resistant buildings.

Design

Our in-house facade design and structural engineering teams are paramount to the success of our projects. Highly-skilled and experienced with parametric and complex design solutions for high-rise unitised schemes, stick curtain wall, rainscreen and reclad projects we value engineer and deliver high-performance facade solutions.

Working closely with clients we develop bespoke systems to suit project design intent, fully tested to CWCT standard. Operating at pre-construction stage, project design and pre-production we utilise both 2D and 3D design using Autodesk software, LogiKal, Sketchup and render software. We partner with the best in the industry and have full knowledge of façade systems including Schueco, Aluprof and Kawneer.

Structural Engineering

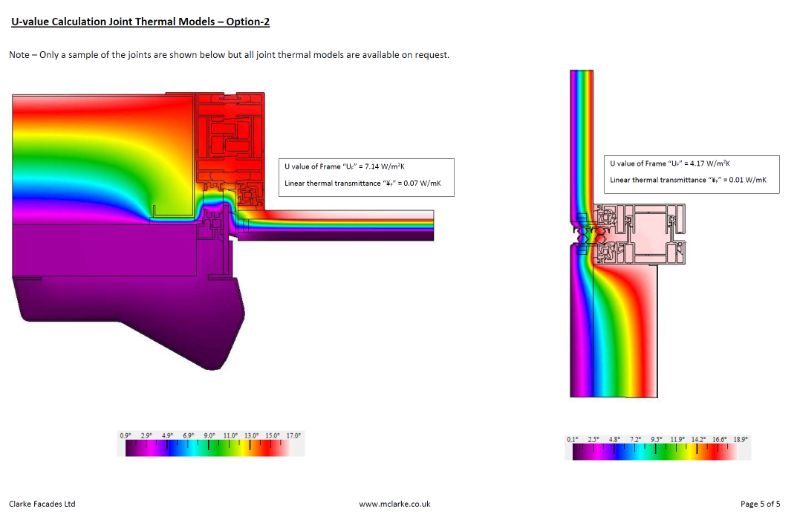

Having in-house structural engineering capabilities is a huge benefit for us and our clients, ensuring our designs are safe, practical and built to deliver highperformance facade solutions. Underpinning the success of our full building envelope as part of our full envelope façade solution our Structural Engineering department carries out a range of services including:

- Structural Engineering

- Finite Element Analysis

- Curtain Wall Engineering

- Bespoke Façade Engineering

- Thermal Analysis

- Acoustic Analysis

- Façade Movement and Tolerances Study

Offsite

Our newly invigorated fabrication facility has state-of-the-art machinery and equipment to allow for lean manufacturing of glazing systems. We are passionate about delivering high quality products to our clients, on time and within budget.

- Offsite unitised façade

- Bespoke offsite architectural elements

- Visual Mock Up / Performance Mock Up

- Stick curtain wall

- Windows, doors, AOV’s, Louvres

Our Offsite Team has over 25 personnel from Pre-production Engineers to Apprentices, Fabricators, Technical Leads and Management. This varied skillset is a huge asset to Clarke, from operating machinery, assembling windows and doors, coordinating visual mock-ups to logistics and delivery. We are keen to mentor and mould talent from local schools and colleges offering apprenticeships as part of our Clarke Growth Academy.

Completing job rotation across our key fabrication areas including factory floor, stores and machine shop gives our apprentices invaluable experience across Clarke Offsite. Our new advanced fabrication facility further cements our position in the market and highlights the commitment to our long-term growth plans. We continually invest in machinery and personnel to maintain our position in the market and sustain relations with key clients in the industry.

Re:Purpose

As a society, and an industry, we have the urgent task of creating a much more sustainable future. The repurposing of our existing built environment is a prime opportunity for us all to play our part. As a business, we have amassed many successful refurbishment projects, where a substantial number of these have been on buildings where the structure remains. Clarke offer the complete Re:Purpose solution for buildings requiring urgent relcad in line with current fire regulations, and architectural refurbishment projects.

Clarke, acting as principal contractor carry out an end to end service, including the following:

Systems:

- Offsite and unitised façade

- Rainscreen cladding

- Window and curtain wall

- Brickslip and render

Offering:

- Existing as-built surveys and inspections

- Concept design and cost proposals

- Full access and site set-up

- Fit-out, demolition and alterations

- M&E Install

- Flat roofing

Before:

After:

Before:

After:

Project Management & Quality

As a specialist façade contractor, we recognise that Health, Safety, Environment and Quality are intrinsic elements underpinning the services we provide to our customers and are at the forefront of our business operations. Adopting Fieldview as our onsite and offsite Quality Management System and by adhering to strict procedures has enabled us to attain an enviably high standard of HSEQ, by adopting a culture of continuous improvement and performance.

Our reliable and highly skilled team of employees who are experienced and qualified in their field are dedicated to project management, installation and client handover. Each project varies on lead time, design and project management requirements, tailoring each scheme to the client’s needs, we deliver a first-class service.

4 Pillars Of

Responsible Business

As well as the environmental impact, we must also direct resource to the other two principles of sustainability; economic viability, and social equity.

Our roadmap over the next 10 years sets out key initiatives and milestones that help us achieve this vision. They are driven and intertwined with our unique values:

Be Brave, Creative, Determined, Collaborative, and Passionate.

The 4 areas of focus are of equal importance, these pillars are benchmarks, that help keep our efforts aligned.

We are very proud to confirm that our Remarkable Sustainable policy is a key area of our long term business strategy. It is vital that sufficient resource is deployed to realise our commitments. This also needs strong governance to ensure we set clear goals, take action, measure and calibrate our performance. We do this by the engagement of the following teams:

- The Board

- Senior Management Team

- Sustainability Committee

The above structure allows us to successfully deliver on our policy objectives across the 4 areas. This enables accountability, transparency, and clear lines of communication. We can then be confident we are a company delivering sustainable growth and positive change.